Technopac

Passion for Packaging

In our company you will find the right packaging for every purpose, certified of the highest quality and manufactured using the latest technologies under the strictest safety conditions. Just like our products, we deliver what we promise.

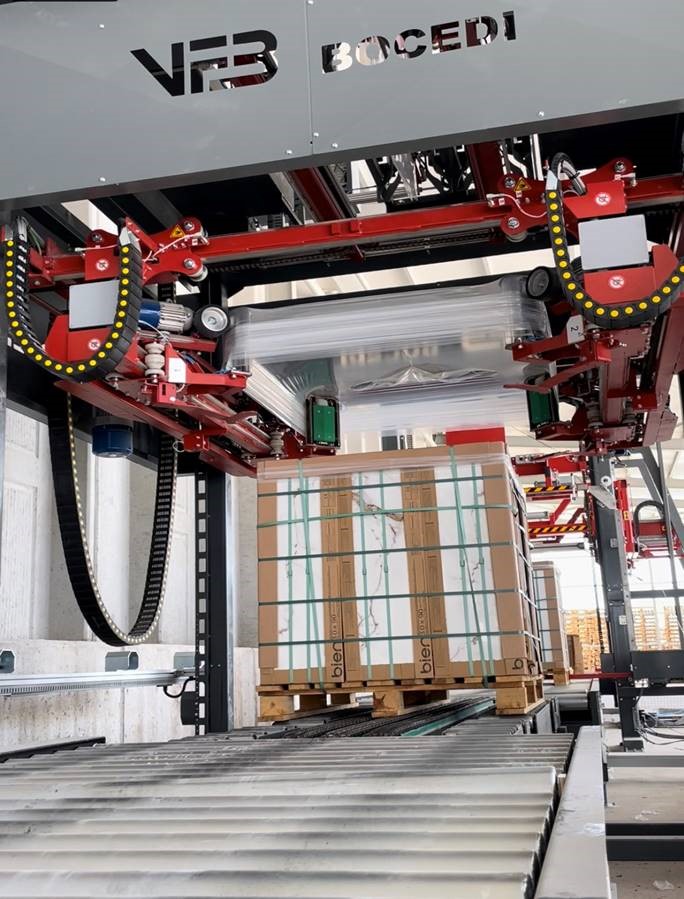

STRETCH-Hood

- Protects products from environmental influences such as rain, sun and dust.

- Keeps stretched products intact, ready for stacking and long distance transport.

- Keeps the stretched product in a safe and transparent shield free from steam traces, even after hot filling, and makes the brand visible.

- Reduces packaging lab costs through automation, plastic waste ratio through automatic dimensional adjustment, and saves energy (<0.07 kW per pallet), by not using expensive thermal energy sources.

- The stretch wrapping speed is up to 60 pallets per hour.

- One film fits different sizes of pallets.

- Easy to use with simple settings.

HOW DO WE PRODUCE STRETCH HOODS?

- We use a 3-layer Co-Ex blow extrusion line.

- We can mix 6 different components per shift via gravimetric feeders for perfect/constant recipes. Human intervention in the recipes is not allowed! Everything is computer controlled!

- Metallocene (C-6 type LLDPEs) and improved versions of the PE series are used only for consistent quality.

- We have alternative raw material series available to introduce in case of possible raw material shortages.

- Introduction of raw materials – extrusion – winding, all automatically controlled. No human intervention!

- All recipes are classified, custom designed and strictly confidential.

WHAT ARE THE DECISIVE FACTORS FOR THE QUALITY OF STRETCH HOODS?

- Coefficient of friction (COF) ➔ Test performed at 100 mm/min speed to determine the COF value by rubbing the same side of the produced film against each other. Optimally performed tests are inner layer – inner layer, outer layer – outer layer and inner layer – metal.

- Elastic recovery ➔ Each plastic component expands and returns to its original shape until it is stretched beyond a point where it cannot return. This point is called the “elastic recovery point” and shows how tight the stretch wrap is on the pallet. The ideal value for the stretch envelope is between 70-80%. Any value below this interval indicates that the envelope is too loose, and any value above this interval indicates that it is too tight.

- Mechanical values ➔ MD & TD Breaking strength and elongation of the film. Constant thickness control during production.